Recycled packaging is gaining popularity for its environmental benefits, such as reducing waste and conserving resources. However, these advantages come with hidden financial and operational challenges, including higher production costs and supply chain complexities.

As companies explore the shift to recycled materials, they must carefully assess the balance between sustainability and profitability. With that, can the environmental benefits outweigh the potential impact on a company’s bottom line?

The Direct Costs of Using Recycled Packaging

Material Sourcing Costs

- Limited availability of recycled materials

- Fluctuating demand leading to price volatility

- Specialized processing requirements

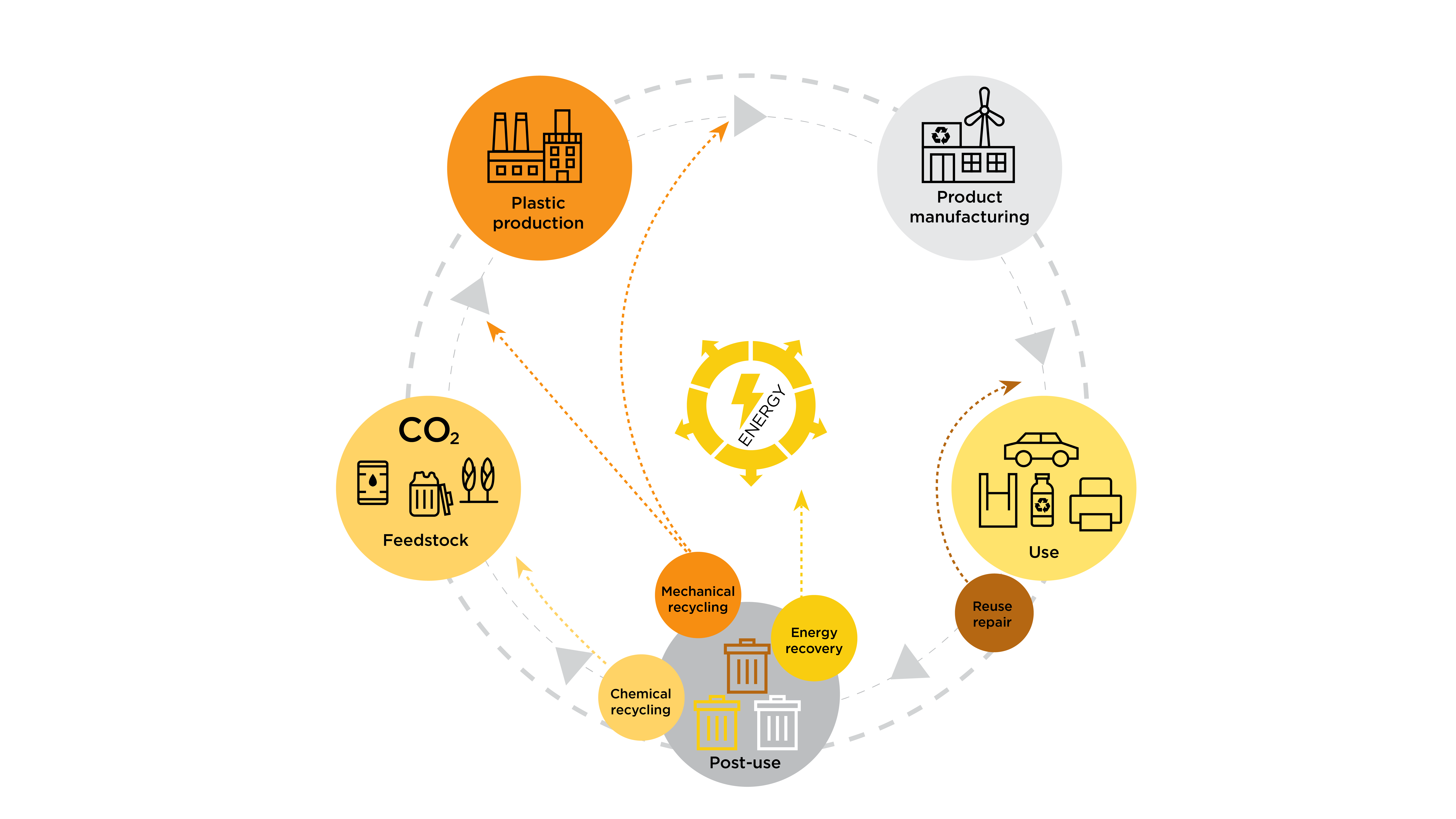

Recycled materials can be more expensive to source due to their limited availability and the specialized steps required for processing, such as recycled PET. According to Plastics Europe, global demand for recycled plastics reached 27.1 million metric tons in 2019, increasing competition for limited supplies, which further drives up costs.

Production Costs

- Machinery modifications and recalibration

- Increased energy consumption and wear on equipment

- Higher defect rates due to material inconsistencies

Working with recycled materials often requires machinery adjustments and increased energy consumption, particularly in high-precision industries. Inconsistent material quality can exacerbate production challenges, leading to machinery wear, downtime, and higher defect rates, which drive up costs.

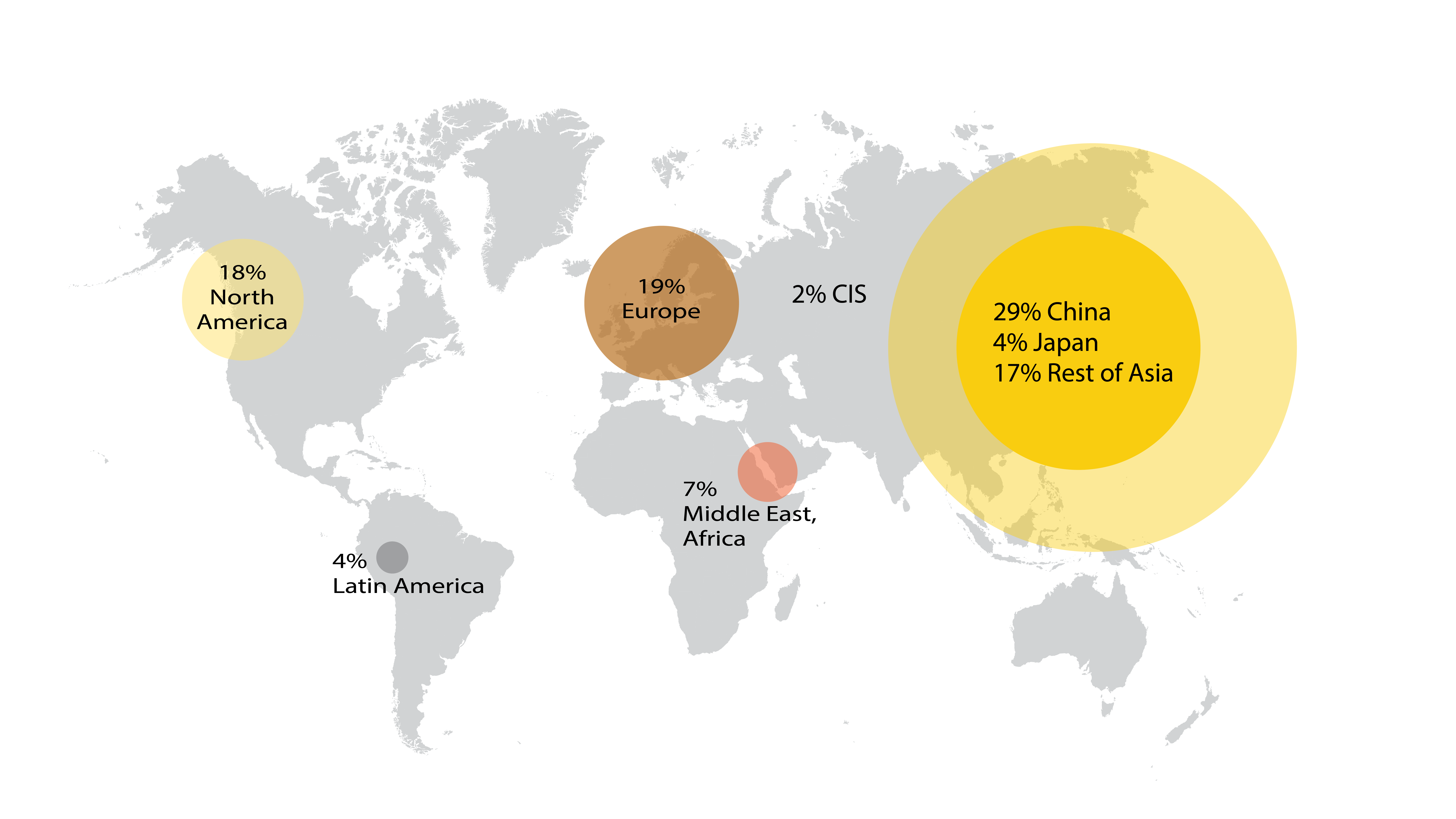

Additionally, with 50% of global plastic production occurring in Asia, predominantly in China (29%), sourcing recycled plastics may also be influenced by geographic disparities in production, adding another layer of complexity to maintaining consistent material quality.

The Indirect and Hidden Costs

Quality and Performance Issues

- Inconsistent material quality

- Higher product defect rates

- Increased returns and customer dissatisfaction

Recycled materials, while environmentally friendly, often exhibit variability in quality compared to virgin materials. This can lead to defects, especially when recycled materials don’t meet performance standards under stress or wear.

For example, recycled plastics might have lower tensile strength or color inconsistencies, impacting both durability and visual appeal. These issues can lead to increased product returns, customer dissatisfaction, and potential reputational damage, making it crucial to weigh the benefits of cost savings against product reliability.

Supply Chain Challenges

- Unpredictable supply availability

- Complex logistics and storage needs

- Potential for production delays

Securing a steady supply of recycled materials can be more unpredictable than sourcing virgin materials due to market volatility. Recycled materials often face delays in collection, processing, and transportation, which can slow down production.

Research shows that only 20.9% of PET plastics are reprocessed globally, making consistent supply a challenge. This limited reprocessing rate frequently results in lower-quality recycled materials, affecting product performance and requiring businesses to manage multiple material types, grades, and cleanliness standards. These complications demand additional logistics and storage, particularly in global manufacturing, leading to higher operational costs and extended time-to-market, which impacts overall production efficiency.

Compliance and Certification Costs

- Regulatory requirements

- Costs of eco-certifications

- Expenses for audits and testing

Meeting regulatory standards for recycled materials, such as achieving eco-certifications or adhering to sustainability targets, can be costly. Certification from organizations like Cradle to Cradle, as well as compliance with regional packaging regulations, involves expenses related to audits, documentation, and testing to ensure materials meet both quality and safety standards.

Environmental and Marketing Trade-offs

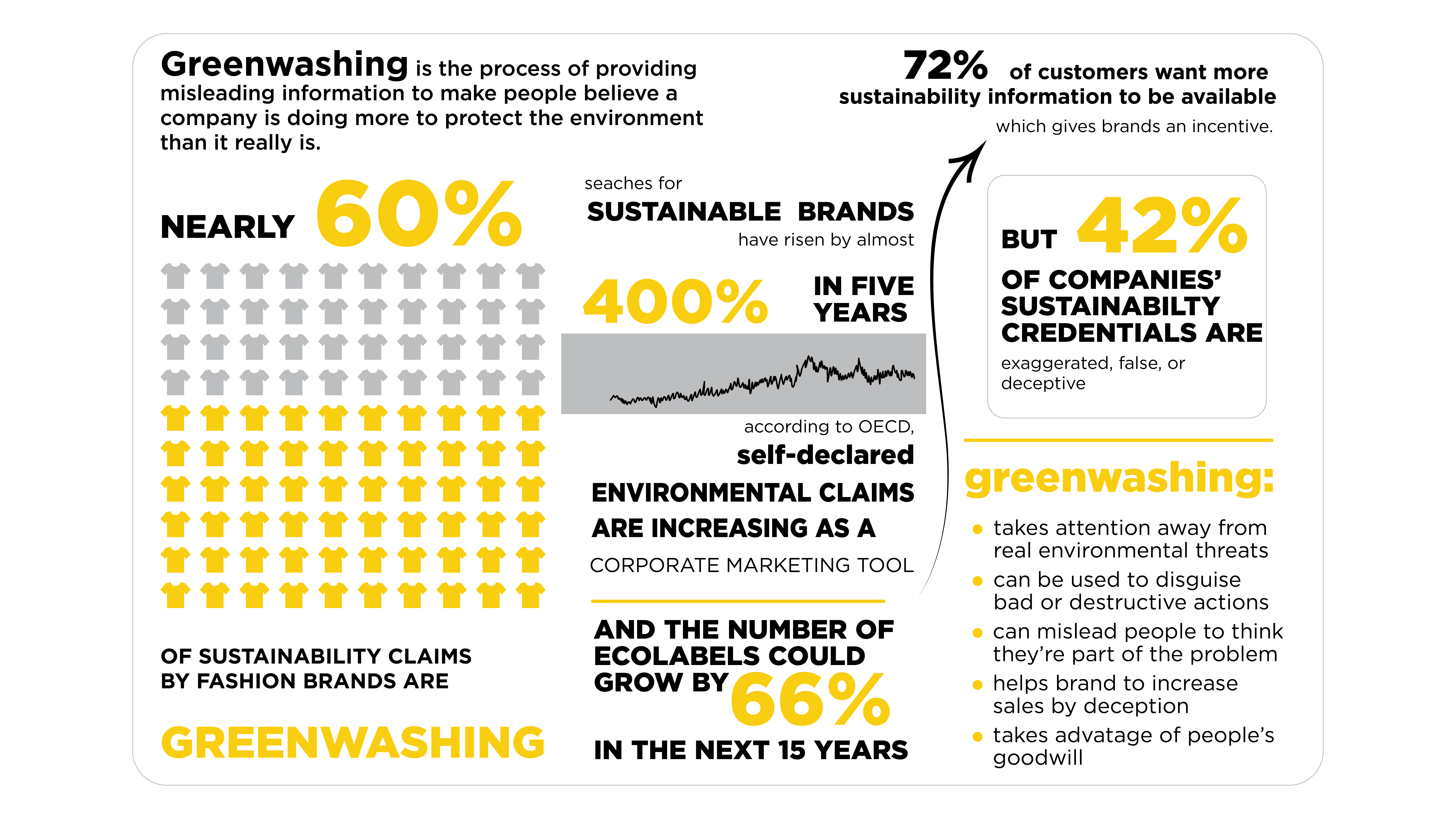

Greenwashing Risks

- Potential reputational damage

- Importance of transparency

- Regulatory scrutiny

Greenwashing, or making misleading claims about sustainability, can result in serious consequences. Brands risk damaging their credibility and losing consumer trust if their claims about environmental practices are exaggerated. Transparency is crucial—businesses should ensure that all sustainability claims, particularly about recycled materials, are backed by verifiable data. In addition, increasing regulatory scrutiny around greenwashing means that companies must adhere to stricter standards to avoid legal consequences.

The Challenge of Recycling Complex Packaging

- Difficult-to-recycle materials

- Long-term environmental impact

- Customer expectations

Recycled packaging can face significant challenges, especially when dealing with complex materials like multi-layered or laminated packaging. These materials are often harder to recycle, leading to higher disposal costs. The long-term environmental impact of using packaging that can’t be effectively recycled can harm a brand’s sustainability efforts.

Moreover, customers expect brands to align their packaging practices with sustainability claims, so failing to meet these expectations can negatively affect brand perception and loyalty. Balancing these challenges is essential for staying true to sustainability goals while maintaining customer trust.

Mitigating the Hidden Costs

Balancing Sustainability with Profitability

- Long-term investment in sustainability

- Eco-friendly branding as a competitive edge

To balance the costs of using recycled materials, companies can focus on long-term sustainability goals that gradually reduce costs while enhancing brand reputation. By positioning eco-friendly branding as a key element, businesses can attract customers who are willing to pay a premium for sustainable products, leading to increased profitability over time.

Partnering with Experienced Suppliers

- Specialized knowledge

- Strong supply chain relationships

Collaborating with experienced suppliers helps mitigate potential pitfalls related to recycled materials. Suppliers with expertise in this area can ensure consistent quality and streamline processes, while strong supply chain relationships reduce the risk of price volatility and supply disruptions, contributing to overall cost savings.

The Future of Recycled Packaging

While using recycled materials in packaging may come with higher initial costs, businesses increasingly see the value in making the switch. As consumer demand for eco-friendly products grows and stricter environmental regulations emerge, adopting sustainable practices becomes not just a choice but a necessity. Companies that fail to transition early may face greater operational and financial challenges in the future. Therefore, it’s crucial to weigh both the benefits and hidden costs and partner with suppliers who understand the complexities of sustainable packaging solutions to remain competitive in an evolving marketplace.

FAQ: The Hidden Costs Behind Recycled Packaging

1. Why does recycled packaging cost more than virgin materials?

Recycled packaging materials often cost more due to limited supply, additional processing like cleaning and sorting, and increased demand. These factors create price volatility, especially in industries like electronics or fashion, where competition for sustainable materials is higher.

2. What are the indirect costs of using recycled materials in packaging?

Indirect costs include inconsistent quality, higher defect rates, unpredictable supply chains, and additional expenses for meeting eco-certifications and regulatory compliance, all impacting operational efficiency and profitability.

3. How can companies mitigate the hidden costs of using recycled materials?

Businesses can mitigate costs by partnering with experienced suppliers, maintaining strong supply chains, and using eco-friendly packaging as part of a long-term branding strategy to attract eco-conscious consumers and offset higher initial costs.

4. What are the risks of greenwashing when using recycled packaging?

Greenwashing risks include reputational damage, loss of customer trust, and regulatory scrutiny if sustainability claims are exaggerated. Transparent, verifiable data on recycled materials is essential to avoid these issues.

5. Are there challenges with recycling complex packaging materials?

Yes, multi-layered or laminated packaging contains mixed materials that are harder to recycle, increasing disposal costs and environmental impacts, which can undermine a brand’s sustainability efforts.

6. How does using recycled packaging affect brand perception?

Eco-friendly packaging enhances brand reputation among conscious consumers. However, misleading claims can result in backlash, harming brand trust and loyalty. Transparency is critical for maintaining credibility.

7. Is recycled packaging necessary for future business success?

With increasing consumer demand for eco-friendly products and stricter regulations, adopting recycled packaging is essential for future competitiveness. Companies that delay this shift risk operational and financial setbacks.