The HealthTech and MedTech sectors have advanced significantly in recent years, holding immense potential to reshape healthcare outcomes.

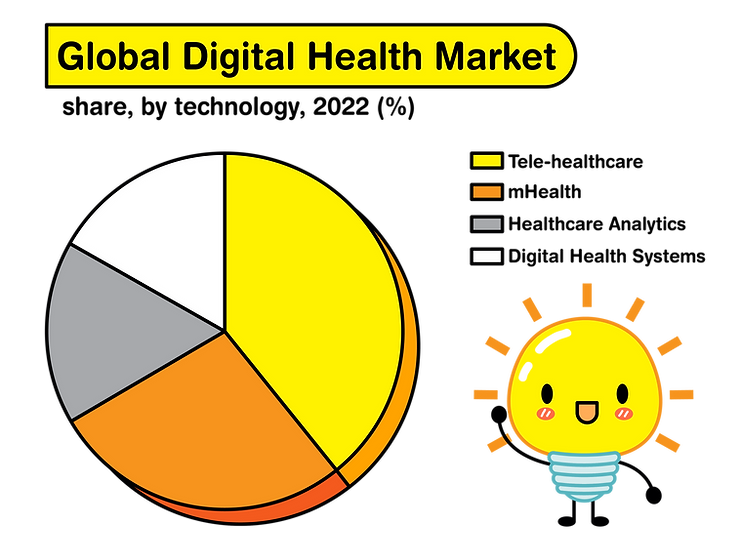

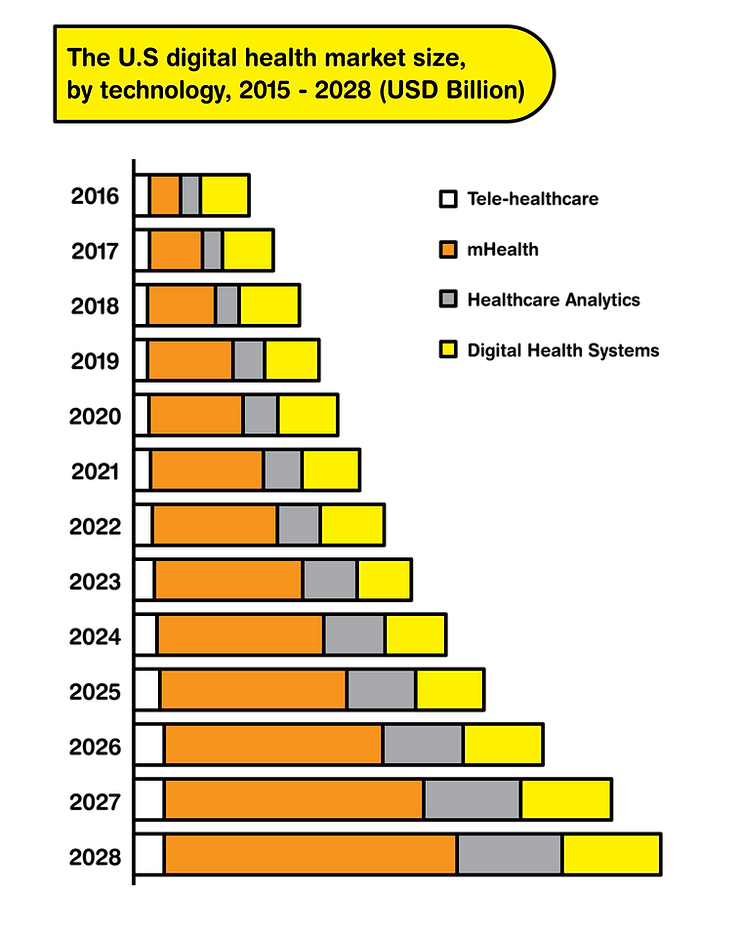

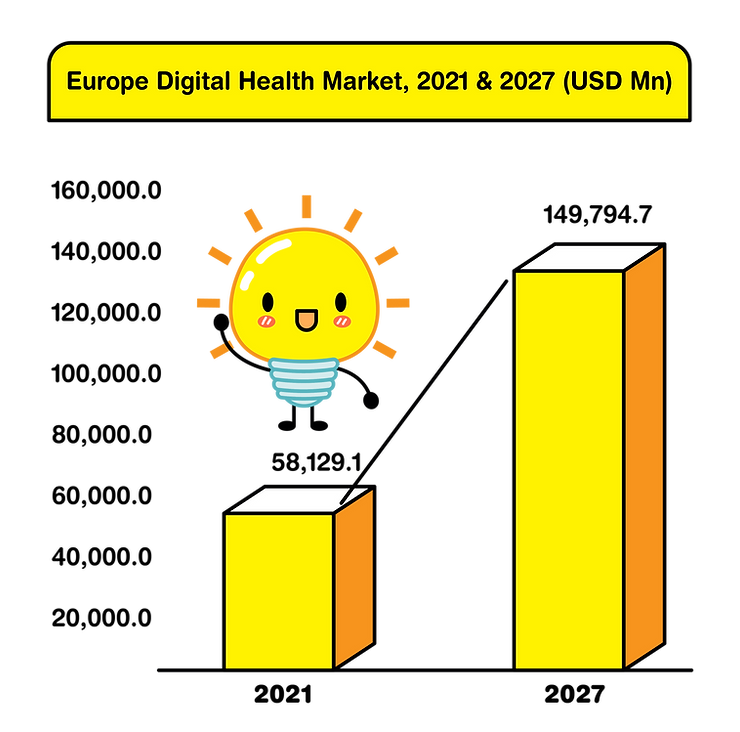

- The global digital health market, valued at USD 96.5 billion in 2020, is projected to grow at a robust CAGR of 15.1% from 2021 to 2028.

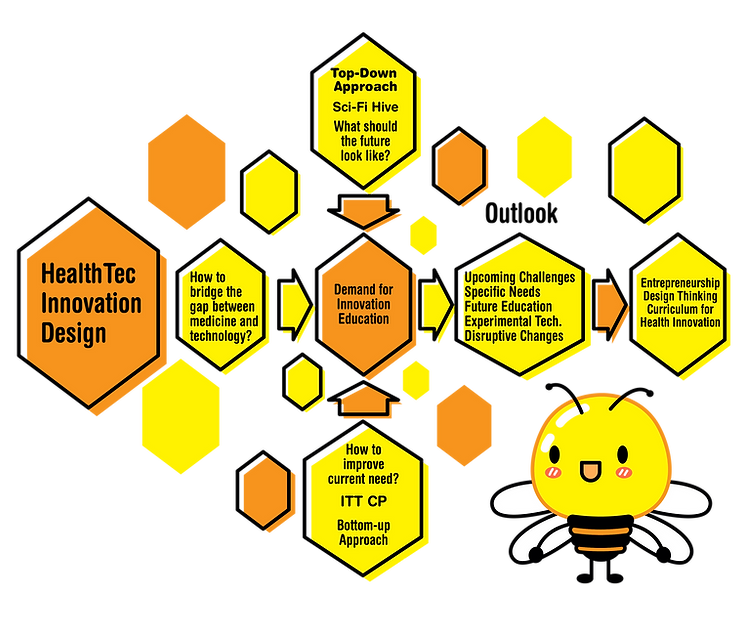

Despite these statistics showing an evident need for healthcare technology, there remains a substantial gap between its potential and current utilization. Design for Manufacturing (DFM) is the crucial bridge. Through effective DFM, we can align healthcare technology precisely with the needs and aspirations of users. We Will cover:

- Defining HealthTech and MedTech: What’s the difference

- What Is The Information Gap in Health and Med Tech?

- Bridging the Gap: User-Centric DFM in HealthTech and MedTech

- Case Studies and Real-world Insights

- Final Thoughts: DFM’s Vital Role in Bridging Healthcare’s Transformational Divide

Defining HealthTech and MedTech in Manufacturing

1) HealthTech DFM:

HealthTech, also known as digital health or e-health, encompasses a broad range of technologies aimed at improving personal health and well-being through the use of technology. The devices measure your data and then give you feedback about it. They aim to improve health through prevention methods and monitoring. However, they don’t focus on the treatment itself. HealthTech includes, for example, telehealth, wearable items, or remote monitoring. It’s about tools or apps that people can use to improve their health without visiting the hospital or any medical facility.

- Examples:

- Mirror: An interactive mirror acting like a home gym and a personal trainer, measuring and displaying performance metrics, and tracking progress over time.

- MonjHealth: A digital nutrition app-improving cooking, eating, and connecting, offering various programs for a healthy lifestyle.

- Muse: A brain-sensing headband measuring brain activity to guide into a restful sleep through biofeedback and calming sounds.

- Application: HealthTech is applied in various settings, including non-clinical environments like homes and workplaces, whereas MedTech is primarily used in clinical settings.

- Scope: HealthTech has a broader scope, encompassing a wide array of technologies and solutions supporting healthcare management and delivery.

2) MedTech DFM:

MedTech, short for Medical Technology, primarily focuses on the development and commercialization of medical devices and technologies. It aims to cure patients better thanks to quicker, more precise analysis, harmless surgeries, less invasive controls, and more.

- Examples:

- Labplus: An automated diagnosis system based on laboratory results and personalized medical history, enabling patients to buy tests and analyze results via an app.

- Hematologist’s Calculator: An app designed for doctors to calculate factors for patient treatment, aiding in medical decisions.

- Touch Surgery: An AR-based tool for medical professionals to learn and practice conducting surgeries via simulations, enhancing surgical accuracy and safety.

- Application: MedTech finds its primary application in clinical settings such as hospitals, clinics, medical laboratories, and other healthcare facilities.

- Scope: MedTech is more specific in scope, focusing on the development, manufacturing, and regulation of medical devices.

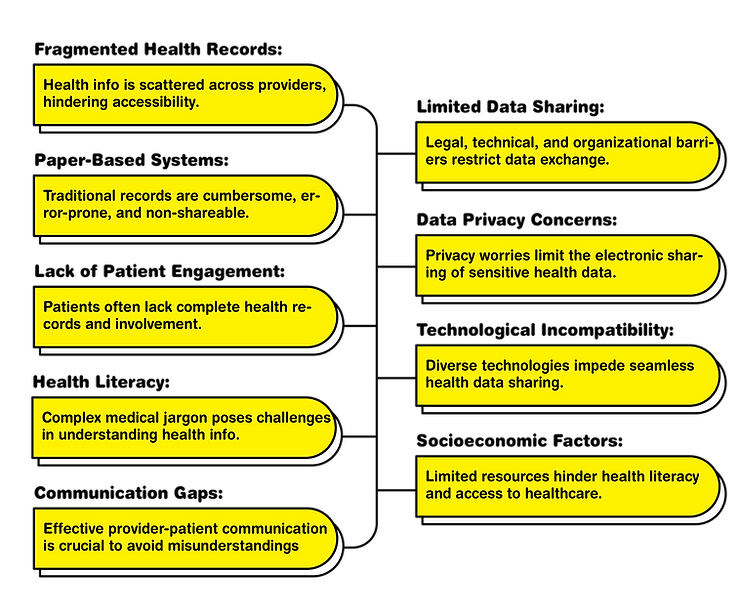

What Is The Information Gap in Health and Med Tech? (For Product Design and Manufacturing)

The “information gap” acts as a significant barrier preventing us from achieving healthcare goals and fostering a truly collaborative patient-provider relationship. This gap means that patients and doctors often don’t have all the necessary information. Vital health details can be missing or not effectively communicated, impeding informed decision-making. From a Design for Manufacturability (DFM) perspective, it’s crucial to consider the demographics of the intended users. If health tech products are designed for an older population with potentially lower tech literacy, the design should prioritize intuitiveness and user-friendliness. Elements like icons, buttons, and user interfaces should be created with the understanding that not all users are tech-savvy.

Moreover, DFM stresses cost-efficiency in health tech design, ensuring affordability for a wide audience. Expensive, complex devices can exclude many due to financial constraints. Education is vital, emphasizing benefits and guiding usage through intuitive features. In essence, closing the information gap requires thoughtful, inclusive, and affordable design following DFM principles.

Bridging the Gap: User-Centric DFM in HealthTech and MedTech

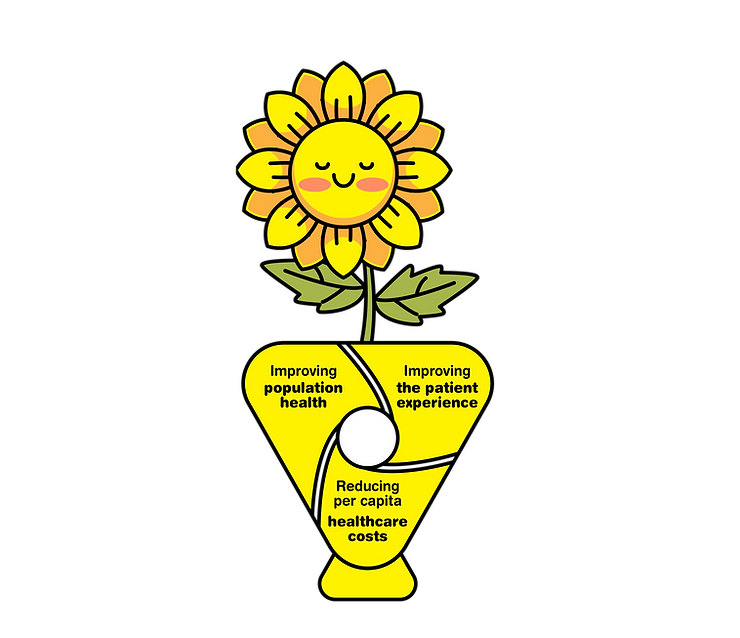

HealthTech, encompassing a wide array of technologies to enhance personal health and well-being, necessitates early integration of Design for Manufacturability (DFM) principles in the design process. This ensures that efficiency and cost-effectiveness are embedded from the outset.

User-Centric DFM for HealthTech

Design for Manufacturability (DFM) is about tailoring HealthTech to meet real user needs. Take, for example, designing a health monitoring app for elderly users. Involving them in the design process ensures the app has larger fonts and a simpler interface, addressing potential tech literacy challenges. The outcome? Better adoption and higher satisfaction among elderly users.

DFM for MedTech Affordability and Accessibility

DFM focuses on simplifying manufacturing processes. Let’s look at a portable diagnostic device as an example. By optimizing the manufacturing, production costs were significantly cut. This cost reduction allowed the company to lower the device’s retail price, making it more affordable and accessible to a wider audience. This, in turn, improves overall healthcare accessibility.

Case Studies and Real-World Insights

Fitbit: Enhancing User Experience through DFM

Design for Comfort and Usability: The wearable health devices are crafted with a deep understanding of user preferences for comfort and ease of use. Design elements like strap materials, clasp mechanisms, and device weight are optimized for prolonged wear, ensuring a seamless user experience.

Precision in Health Tracking: DFM is crucial in ensuring the precision and accuracy of health tracking features. Fitbit devices are engineered to deliver precise data on activities, heart rate, sleep patterns, and more. The integration of sensors and the design of their placement within the device are carefully planned to provide accurate health insights to users.

Battery Life Optimization: Fitbit optimizes battery life, a critical aspect of wearable devices. DFM principles guide the selection and integration of battery components to strike the right balance between performance and longevity, meeting the expectations of users who demand sustained usage between charges.

GE Healthcare Revolution CT Scanner: Elevating Medical Imaging through DFM

Streamlining Manufacturing Processes: DFM plays a pivotal role in the manufacturing of GE Healthcare’s Revolution CT Scanner. The manufacturing process is streamlined and optimized to reduce production time and costs without compromising the scanner’s quality. This efficiency ensures that the scanners can be produced and delivered to healthcare facilities promptly and economically.

Enhanced Quality and Reliability: DFM principles are employed to enhance the overall quality and reliability of the CT scanner. By meticulously designing the components and their assembly, GE Healthcare ensures that the scanner functions optimally and consistently, meeting the demanding standards of medical imaging.

Cost-Effectiveness for Wider Accessibility: Through DFM, GE Healthcare achieves cost-effectiveness in manufacturing. The optimization of manufacturing processes translates to cost savings, enabling GE Healthcare to offer the Revolution CT Scanner at a price point that is more accessible to a broader range of healthcare facilities, thus advancing healthcare accessibility and patient care.

In both case studies, DFM emerges as a fundamental guiding principle that not only shapes product design but also influences manufacturing efficiency, product quality, and ultimately, the positive impact on users and the healthcare ecosystem.

https://youtube.com/watch?v=GzM9SSSDmTQ%3Fautoplay%3D0%26mute%3D0%26controls%3D1%26origin%3Dhttps%253A%252F%252Fwww.gizmospring.com%26playsinline%3D1%26showinfo%3D0%26rel%3D0%26iv_load_policy%3D3%26modestbranding%3D1%26enablejsapi%3D1%26widgetid%3D3

Final Thoughts: DFM’s Vital Role in Bridging Healthcare’s Transformational Divide

Design for Manufacturability (DFM) can play a pivotal role in closing the gap in healthcare transformation. By focusing on making healthcare technologies efficient, cost-effective, and aligned with user needs, DFM acts as the linchpin that connects potential with reality. It’s the bridge that ensures innovations are not just groundbreaking in theory but also accessible and impactful in practice, propelling the healthcare industry toward a future where technology truly transforms lives.