Imagine spending 40 percent less time and 25 percent less labor developing a new product. Not only does this product reach your customers more quickly, but it is also more cost-effective. This dream scenario is not too good to be true; it is achievable through a practical manufacturing technique known as Design for Manufacturability and Assembly (DFM/A). What’s more, implementing DFM/A is surprisingly efficient in terms of both time and effort.

This Article Will Cover:

- What is DFM/A

- Unlocking Manufacturing Efficiency with DFM/A

- Time-to-Market & Sustainability

- Cost-Effective Manufacturing Through DFM/A

- DFM/A in Action

- The Future of Design for Manufacturing and Assembly (DFM/A)

What is DFM/A?

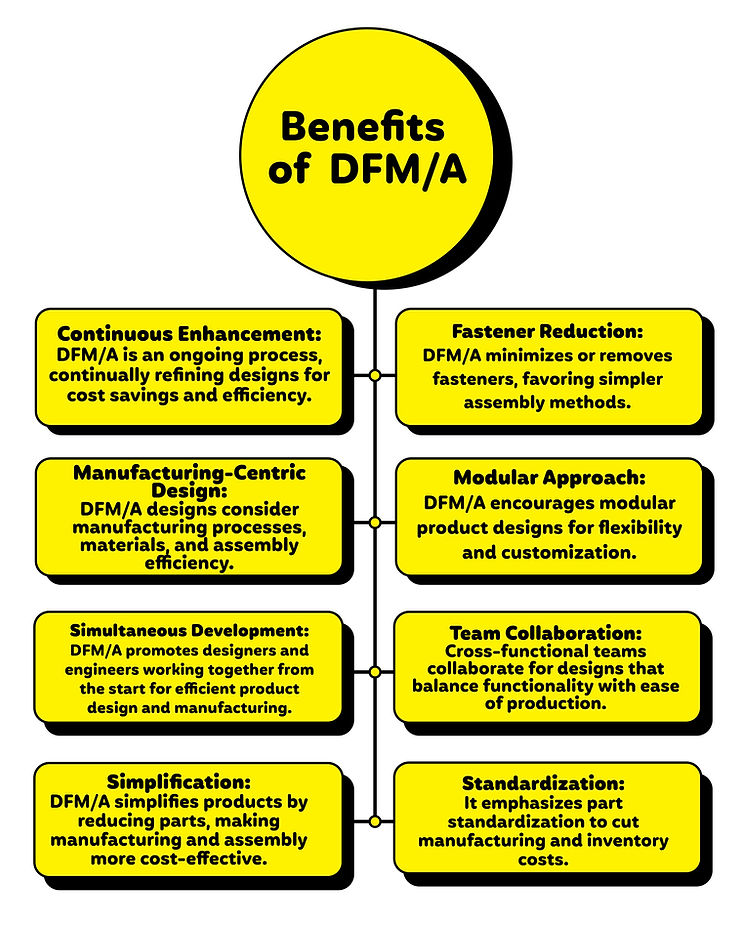

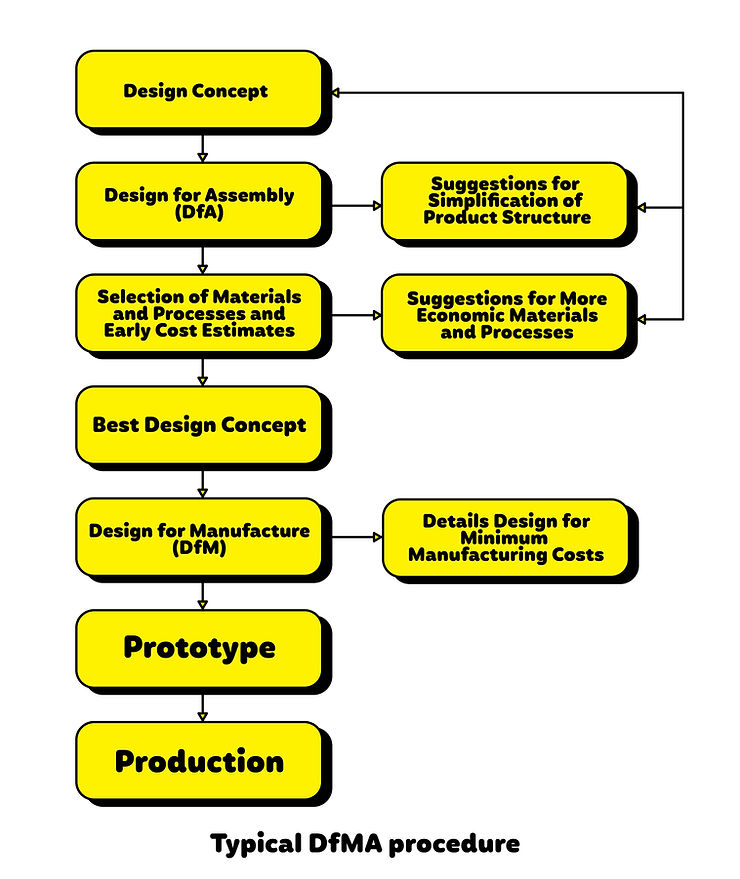

Design for Manufacturability and Assembly (DFM/A) is a strategic approach that represents a fundamental shift in the way products are designed and manufactured. At its core, DFM/A seeks to eliminate inefficiencies and streamline the entire product development process.

Unlocking Manufacturing Efficiency with DFM/A

Picture this: a 40% reduction in the time it takes to develop a new product, along with 25% less effort required. This new product not only gets to your customers quicker but also costs much less to create and manufacture. Some companies are already achieving an optimal blend of speed, quality, and efficiency using a pragmatic DFM/A manufacturing approach, as per insights from John Ingalls’ research study.

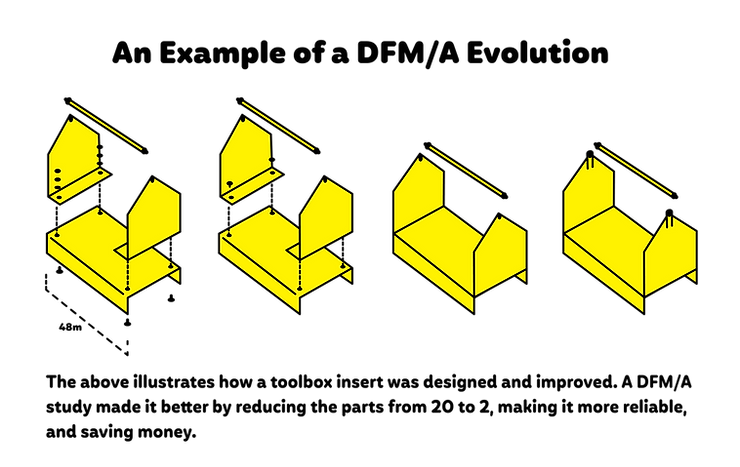

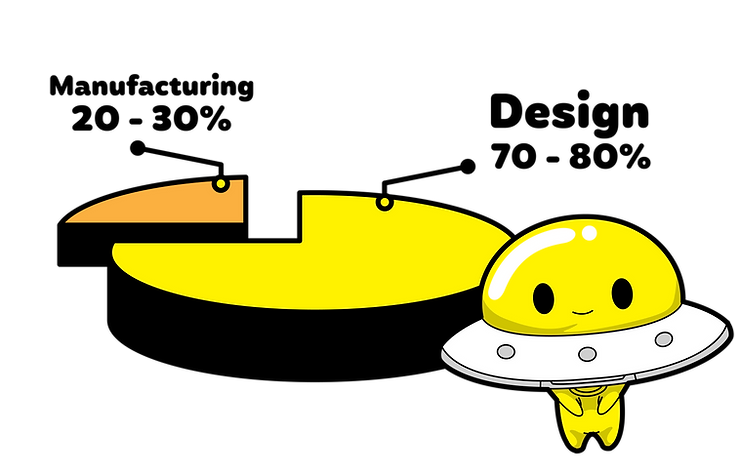

DFM/A is all about designers and manufacturing engineers collaborating right from the start. While designers focus on the aesthetics and influences of a product, engineers consider the technical aspects, capabilities, and limitations. The results are impressive: on average, DFM/A reduces time-to-market by 25%, cuts down the number of parts by 15-20%, trims assembly time by up to 40%, and lowers annual production costs by 5-10%. In an age where efficiency is king, DFM/A shines as the way to manufacturing greatness.

Time-to-Market & Sustainability

Think of DFM/A as intelligent architectural blueprints, meticulously crafted to curtail material usage, bolster cost-effectiveness, and champion environmental preservation by drastically minimizing waste. Construction alone contributes to 40% of global waste production, alongside a quarter of worldwide carbon emissions.

Now, contemplate the conventional construction practices, often synonymous with resource-intensive and environmentally detrimental processes. But with DFM/A principles, you’re engineering a transformative shift. These principles not only expedite construction but also enhance manufacturing practices across diverse industries. They deliver not only timely and cost-efficient outcomes but also pave the path towards a greener, more sustainable future. It’s a holistic synergy that an increasing number of industries are embracing – a journey towards a swifter, environmentally-conscious tomorrow.

Cost-Effective Manufacturing Through DFM/A

DFM/A, guided by its principles, stands as a powerful financial asset for businesses. These practices enable streamlined manufacturing, cost reduction, and early issue identification, minimizing the need for expensive revisions. The adoption of standardized components and materials further bolsters procurement efficiency, delivering significant bottom-line advantages.

As stated earlier, implementing these principles for launching new products has shown a 40% reduction in development time and a 25% decrease in labor investment. These real-world results underscore the tangible financial advantages of DFM/A, spanning the entire product lifecycle and enhancing overall cost-effectiveness for businesses. To illustrate the potential impact, consider this hypothetical scenario: By integrating DFM/A, a company reduces production costs by $0.20 per product, resulting in daily savings of $25,000. In comparison, the one-time expense of partnering with an engineering advisor is vastly outweighed by annual savings amounting to $9.125 million. This emphasizes the substantial and sustainable financial gains achievable through DFM/A.

DFM/A in Action

Apple Inc. is renowned for its innovative product designs and high-quality electronics. The company has consistently applied DFM/A principles to achieve efficient manufacturing processes, reduce costs, and deliver exceptional products.

Streamlined Product Design: Apple’s product designs, from iPhones to MacBooks, exemplify DFM/A principles. They prioritize simplicity in product design, minimizing the number of components and ensuring they are easy to assemble. For example, the unibody MacBook design reduced the number of parts and simplified assembly, improving efficiency and reducing production costs.

Material Efficiency: Apple places a strong emphasis on material efficiency. They use recyclable materials and ensure components are easily disassembled for recycling or repair. This not only aligns with sustainability goals but also reduces material costs.

Supply Chain Efficiency: Apple works closely with suppliers to optimize manufacturing processes. They have been known to invest in supplier facilities to improve production efficiency and quality. This collaborative approach ensures that components are manufactured with DFM/A in mind.

Results:

Cost Reduction: Through DFM/A principles, Apple has achieved significant cost reductions in manufacturing. By simplifying designs, minimizing parts, and optimizing the supply chain, they’ve saved substantial production costs, contributing to their impressive profit margins.

Quality and Reliability: DFM/A has enabled Apple to maintain high product quality and reliability. Fewer components and simpler assembly mean fewer opportunities for defects, leading to improved product performance and customer satisfaction.

Sustainability: Apple’s commitment to DFM/A extends to sustainability. They’ve reduced the environmental impact of their products by using recycled materials and designing for easy disassembly and recycling.

Market Performance and Customer Satisfaction:

Apple’s success with DFM is evident in its strong market performance and customer satisfaction. Despite the higher price point, Apple’s share of the global smartphone market was about 23% in 2022. This market share reflects both the quality and desirability of their products, driven in part by their efficient manufacturing processes enabled by DFM/A.

The Future of Design for Manufacturing and Assembly (DFM/A)

DFM/A is poised to revolutionize manufacturing and product development. Its significance extends beyond cost savings, with the potential to address complex supply chain challenges and boost profitability. This approach, which emphasizes designing products for efficient and cost-effective manufacturing, is crucial in an era of globalization and demand for customized products.

To implement DFM/A effectively, engineers must consider the entire product lifecycle from the outset, understanding the manufacturing processes involved. However, there’s a growing gap between design engineers and the manufacturing process, hindering efficiency. Bridging this gap and promoting cross-pollination of skills between engineers and manufacturers is essential. DFM/A not only streamlines current operations but also future-proof designs, making them adaptable to evolving technologies and automation. As manufacturing becomes more customized and technology-driven, DFM/A is the key to efficiency, cost savings, and rapid market responsiveness, shaping the future of product development.