CORkCICLE.

A Lid Iteration for Sports Jug and Canteen

This project involved designing two lids for the client, encompassing everything from industrial design to final mass production and logistics services. Throughout the project, we explored numerous opportunities and overcame various technical issues and production challenges. Ultimately, we succeeded in bringing two lids to reality.

How we work

The road to success in building a product is long and challenging, often requiring the expensive services of multiple companies. Gizmospring sets itself apart from competitors by offering a full range of in-house services, making us a true one-stop shop.

Requirement

Confirmation.

We start from Listening

We maintained ongoing communication with our client, Corkcicle, throughout product development. By involving clients in every stage, we provide updates and encourage their engagement. We often present multiple solutions to a single problem and discuss critical issues in detail. At Gizmospring, we prioritize transparency and strive to maintain a collaborative relationship with our clients.

OBJECTIVE

Industrial

design.

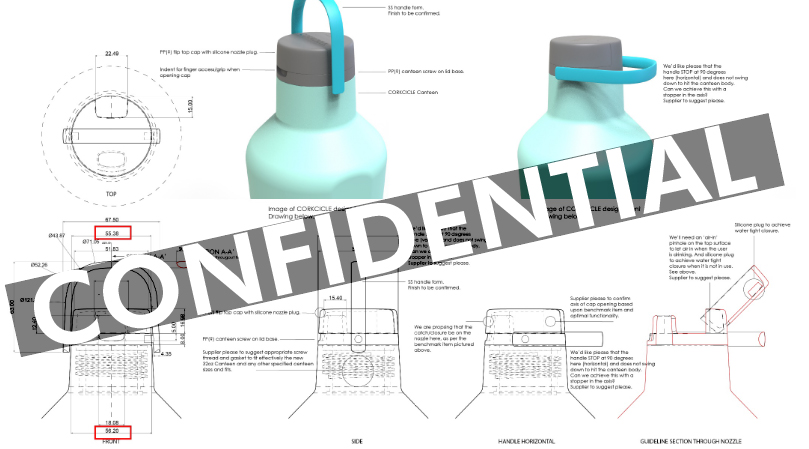

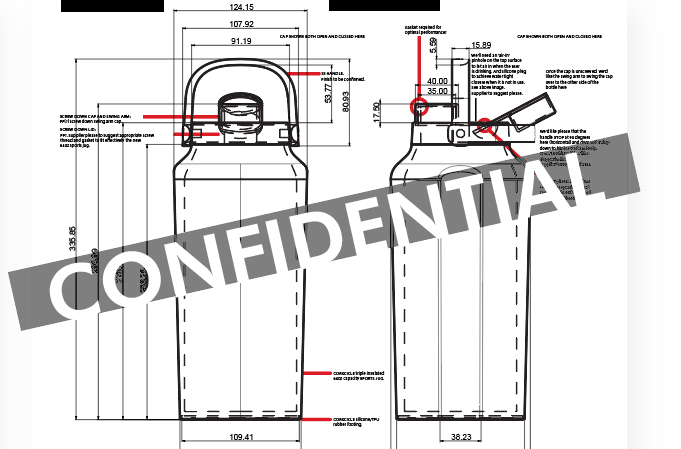

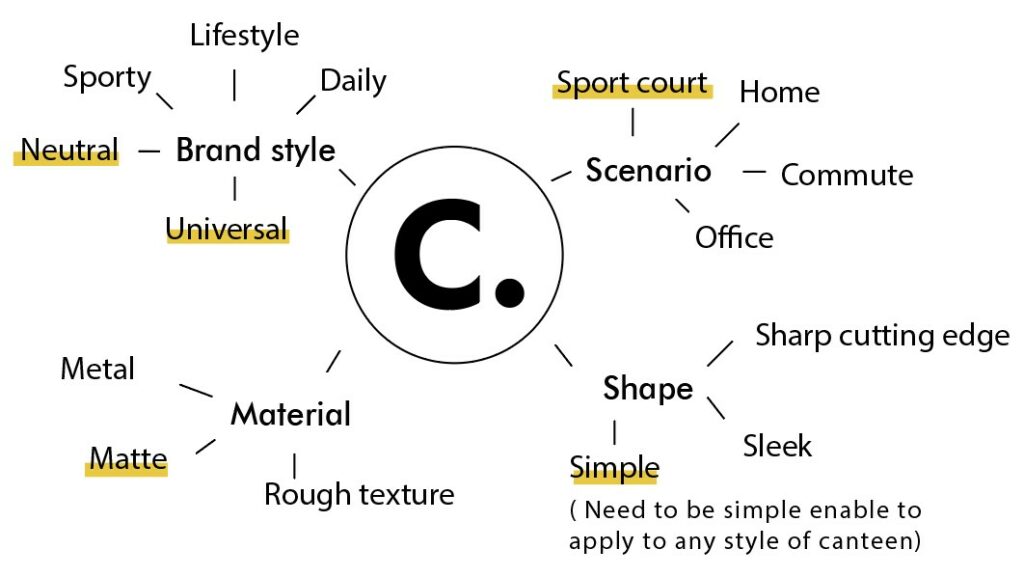

Analyze Brand

We began with a thorough assessment of the rough 2-dimensional drawings and specification requirements provided by our client, Corkcicle. After studying benchmarks and conducting market research, we offered suggestions and analyzed the design language of Corkcicle products, collecting relevant references. Using this information, we developed the shape and form of the lids in line with our research findings.

USER

- All genders

- Commuters

- The younger generation

- People who catch on trends

Features

- Quick sip

- No straw

- Foldable handle

- Reconizable brand identity

Industrial

design.

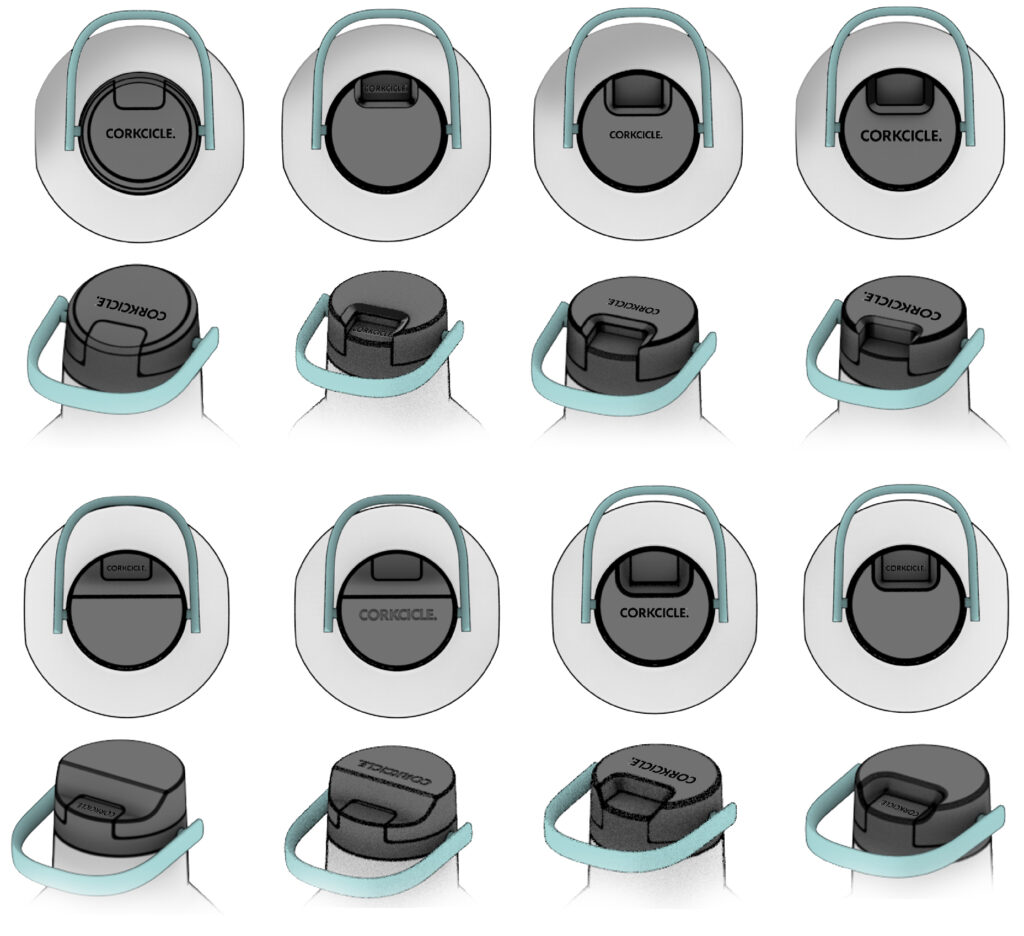

Explore Shape

During the shape and form development process, we aimed to create a design for the two lids that was as simple as possible to complement the diverse style of the canteen body while maintaining consistency with CORKCICLE’s product line. We emphasized simplicity in volume while focusing on detailed design elements. In the exploration stage, we experimented with various finishes, patterns, and layouts, using contrasting textures and spacing to enhance the product’s delicacy and sophistication.

industrial design.

engineer design.

prototyping.

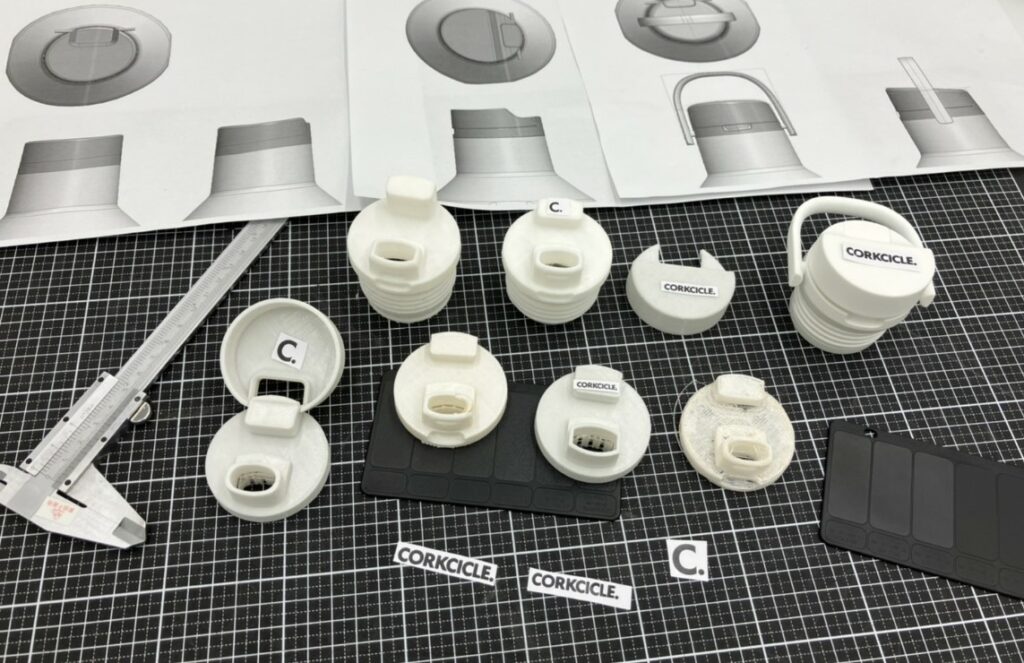

Improve Experience

During the shape and form development process, we aimed to keep the design of the two lids as simple as possible to complement the diverse styles of the canteen body while maintaining consistency with CORKCICLE’s products. We focused on simplicity in volume while emphasizing detailed design. In the exploration stage, we experimented with various finishes, patterns, and layouts, using contrasting textures and spacing to enhance the product’s delicacy and sophistication.

tooling &

mass production.

Finalize & Realize Details

- We applied various metal processes to maximize the durability of the lids.

- We tested different hardness levels and shapes for the sealing silicone to prevent water leakage.

- We conducted pressure tests to ensure the lid could be opened with moderate strength while enduring multiple washing machine cycles.

- We studied the location of screws and made necessary adjustments to align with the new lid design.

- We confirmed that the Color, Material, and Finish (CMF) of the final product from the factory met our design standards.

In this final stage, we work closely with our factory to ensure smooth production. This includes checking Design for Manufacturability (DFM), addressing issues related to injection, materials, and other mass production challenges. We also make subtle final tweaks. Before shipping, we conduct various tests, such as durability and press tests, as per the client’s request to ensure quality.