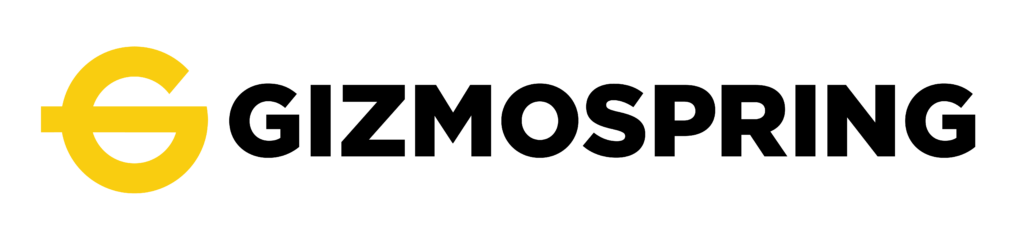

Establishing a strong relationship with your suppliers is foundational for any successful business. This partnership, often long-term in nature, is not just a transactional interaction but a strategic alliance that can significantly impact your company’s efficiency, product quality, and overall market competitiveness. Choosing the right supplier involves a careful evaluation of various factors, such as quality, reliability, cost, and ethical practices, which ensures alignment with your business objectives and values. Asking the right questions before committing to a supplier can safeguard your business against unforeseen issues and pave the way for a fruitful and collaborative relationship that can adapt and grow with your business needs.

1) How do you ensure and maintain the quality of your products or services?

When assessing the quality of products or services offered by a supplier, it’s essential to delve into their quality control and assurance processes. Ask if they adhere to internationally recognized standards like ISO 9001, which demonstrates a commitment to consistent quality and continuous improvement. For example, a supplier in the electronics industry might have specific certifications like ISO/TS 16949, vital for automotive sector supplies, indicating rigorous quality standards. Additionally, enquire about their internal quality audits, process controls, and how they handle non-conformities. A supplier with robust quality measures not only ensures product reliability but also reflects their dedication to delivering excellence, which is crucial for maintaining your business’s reputation and customer satisfaction.

2) Can you provide evidence or examples of your ability to consistently meet delivery deadlines?

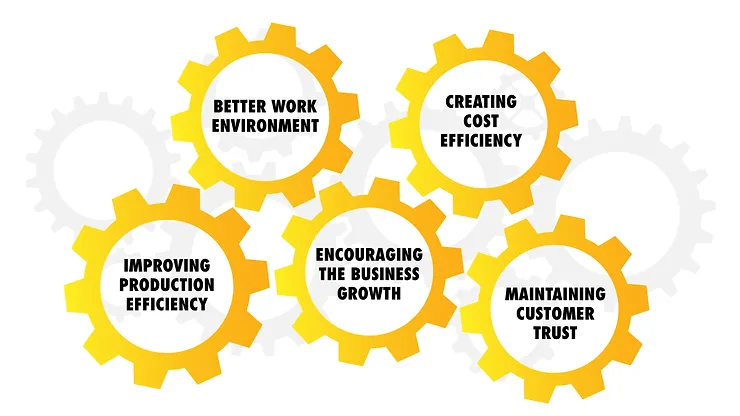

Production reliability refers to the ability of a manufacturing system to consistently produce products or services without interruptions or failures. It is a measure of the system’s dependability and consistency in meeting production requirements. This concept is closely linked to reliability and timeliness in supply chains, as a reliable production system is more likely to meet delivery deadlines, ensuring products are delivered on time to customers and preventing delays that can disrupt operations or customer satisfaction.

- Operations Process Reliability: Consistency in the production process.

- Maintenance Equipment Reliability: Upkeep and functionality of production equipment.

- Engineering Lifecycle Cost (LCC): Cost-effective design and operation over a product’s lifespan.

Hence, it’s crucial to determine if a supplier can consistently meet delivery deadlines as this directly impacts your operations and customer satisfaction. Investigating their track record in this area involves looking into their history of on-time deliveries, how they handle logistic challenges, and their responsiveness in critical situations. For instance, a supplier with a high percentage of on-time deliveries in the fast-paced consumer goods industry is likely more reliable than one with frequent delays. It’s also wise to ask for references or testimonials from existing clients to verify their reliability and promptness.

3) What is your pricing structure, and are there any hidden costs or discounts available?

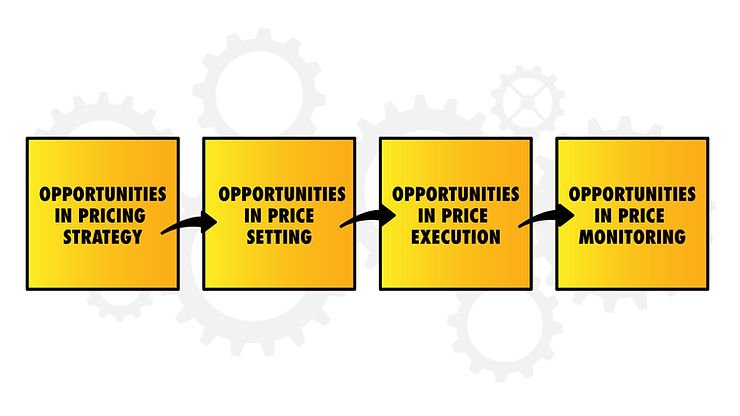

Understanding the supplier’s pricing structure is crucial to ensure it aligns with your budget and profitability goals. Inquire about any hidden costs, fees, or discounts available for long-term partnerships. Transparency in pricing is essential to avoid unexpected expenses that could impact your bottom line.

Examples of Pricing Strategies: Opportunities in Pricing Strategy

Segmentation: Tailoring pricing strategies to different customer segments based on factors such as volume of purchase, sensitivity to price, and the value they derive from the product. This allows for more targeted pricing and can increase profitability.

Integrating Pricing Research into Strategy: Utilizing market research and data analytics to understand customers’ willingness to pay, competitors’ pricing, and the perceived value of the product. This information guides strategic pricing decisions.

Implementing Value-Based Pricing Best Practices: Setting prices based on the value perceived by the customer rather than solely on costs or market standards. This requires a deep understanding of the value your product provides and how it differs from competitors.

Opportunities in Price Setting

Leveraging the Pricing Waterfall: Understanding all the factors that can affect the final price, such as list price, discounts, allowances, and payment terms. This helps in identifying where money is left on the table and where there are opportunities to optimize pricing.

Developing Customer-Facing Price Negotiation Tools: Creating tools or systems that enable sales teams to have informed discussions with customers about pricing. These tools can provide real-time information on discounts, volume breaks, and value propositions to support effective negotiations.

Opportunities in Price Execution

Increasing Sales Effectiveness and Volumes with Pricing Guides: Providing sales teams with clear pricing guidelines to help them make quick and accurate decisions in the field. This can improve sales effectiveness and drive volume growth.

Collecting Market Intelligence: Continuously gathering and analyzing data on market trends, competitor pricing, and customer feedback to make informed pricing decisions. This intelligence can help in adjusting strategies swiftly to market changes.

Opportunities in Price Monitoring

Developing Pricing KPIs: Establishing key performance indicators (KPIs) to measure the effectiveness of pricing strategies. These metrics can include things like price realization, margin leakage, and compliance with pricing policies.

Creating Visibility into the ‘Window’ for Price Increases: Monitoring the market and internal cost structures to identify the right timing for price increases. This involves understanding the factors that can influence the acceptance of price changes, such as inflation, commodity prices, and demand elasticity.

Hidden Costs

- Setup Fees: One-time charges for setting up an account or service.

- Service Fees: Charges for additional services like installation or maintenance.

- Cancellation Fees: Penalties for ending a contract early.

- Overage Charges: Extra fees for exceeding agreed-upon limits in volume-based deals.

Discounts and Savings

- Long-Term Contracts: Suppliers may offer discounts for committing to a longer-term contract.

- Early Payment Discounts: Reduction in cost for paying invoices early.

- Bundled Services: Discounts for purchasing multiple services or products together.

- Loyalty Programs: Rewards or discounts for long-term customers.

Negotiation Tips

- Understand Total Cost of Ownership (TCO): Look beyond unit price to understand all costs associated with the product or service.

- Ask for Transparency: Request a detailed breakdown of all costs and fees.

- Explore Customization: Inquire if pricing can be tailored to your specific needs.

- Discuss Future Scalability: Ensure the pricing structure can accommodate future growth or changes in demand.

- Leverage Competition: Use quotes from multiple suppliers to negotiate better terms.

Smart Tip: Working with an all-in-one and vertically integrated supply chain partner can offer enhanced customization in pricing. Such partners control multiple stages of production and distribution, providing greater flexibility to tailor pricing models to your specific needs. This integration can lead to more efficient cost structures, potential for bundled pricing, and a streamlined approach to modifying terms as your business requirements evolve. This unique position often allows these suppliers to offer more competitive and adaptable pricing solutions, aligning closely with your operational and financial objectives.

4) What is your contingency plan for disruptions in the supply chain?

In today’s global marketplace, supply chain disruptions can be a significant challenge. Inquire about the supplier’s contingency plans for handling unforeseen events like natural disasters or geopolitical issues. A robust contingency plan ensures minimal disruption to your operations.

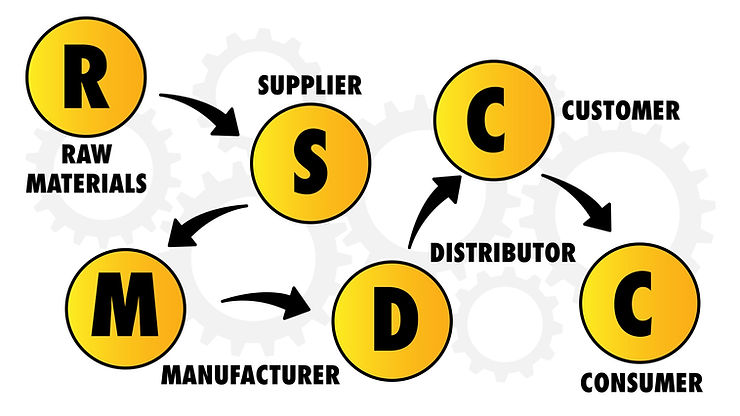

- Raw Materials (R): The base inputs required to produce goods.

- Supplier (S): Entities that provide the raw materials.

- Manufacturer (M): The producers who turn raw materials into finished products.

- Distribution (D): The process of getting the finished product to the market.

- Customer (C): Businesses or entities that buy the product for resale or use.

- Consumer (C): The final buyers who purchase the product for personal use.

Incorporating this flow into the key components of supply chain contingency planning involves ensuring that each stage has a backup plan to handle disruptions:

- Raw Materials (R):

- Risk Management: Identify alternative sources of raw materials to mitigate the risk of supply shortages.

- Inventory Management: Keep safety stock of essential raw materials to buffer against supply chain disruptions.

- Supplier (S):

- Diversified Supplier Network: Maintain relationships with multiple suppliers to avoid reliance on a single source.

- Communication Strategy: Develop protocols for rapid communication with suppliers in case of supply chain interruptions.

- Manufacturer (M):

- Flexible Production: Have the ability to scale production up or down based on material availability and demand.

- Technological Integration: Use technology to monitor production processes and quickly adapt to supply changes.

- Distribution (D):

- Flexible Transportation and Logistics: Secure contracts with multiple carriers and diversify transportation routes.

- Financial Resilience: Prepare for the additional costs that might come from expedited shipping or rerouting products.

- Customer (C):

- Communication Strategy: Ensure transparent communication about product availability and delivery schedules.

- Order Management: Have systems in place to manage changes in order volume and prioritize customers if supply is limited.

- Consumer (C):

- Customer Service: Strengthen customer service to handle inquiries and complaints during disruptions.

- Market Intelligence: Stay informed about consumer needs and market trends to adjust quickly to changes in consumer behavior.

Each stage of the supply chain requires a tailored approach to contingency planning to ensure the overall resilience of the supply chain. By considering the specific risks and needs at each stage, companies can develop a robust contingency plan that minimizes disruption, maintains trust, and protects the financial and operational health of the business.

5) How do you handle intellectual property (IP) protection?

If your products or processes involve proprietary technology or designs, inquire about the supplier’s approach to IP protection. Ensure they have measures in place to safeguard your intellectual property, reducing the risk of theft or unauthorized sharing.

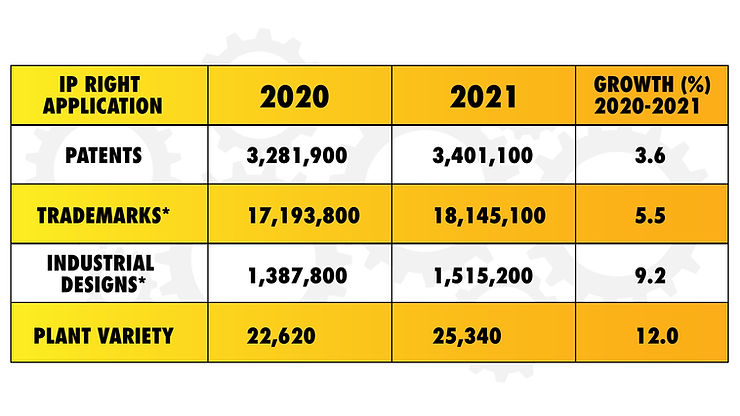

Intellectual property (IP) protection is paramount for businesses that rely on proprietary technology, designs, or processes to maintain their competitive advantage. The significance of robust IP protection includes safeguarding competitive edges, securing revenue streams from licensing, protecting R&D investments, maintaining brand integrity, and fostering innovation. Given that the World Intellectual Property Organization (WIPO) reported an impressive submission of 3.4 million patent applications globally in 2021, this underscores the immense value that companies place on their innovations and the need for stringent protective measures.

To manage IP protection with suppliers, businesses should:

- Draft Comprehensive Contracts: Ensure contracts include non-disclosure agreements (NDAs) and explicit IP rights clauses.

- Implement Access Controls: Restrict access to confidential information to essential personnel.

- Conduct Regular Audits: Perform audits to monitor compliance with IP protection protocols.

- Provide Training: Educate suppliers on the importance of IP laws and the consequences of infringement.

The statistic from WIPO serves to highlight the vast scale of innovation worldwide and the critical need for mechanisms to protect these intellectual assets. It is essential to choose suppliers that demonstrate a commitment to IP protection to minimize the risk of IP theft or unauthorized distribution.

6) Can you share references or case studies from past clients or projects?

Requesting references and case studies from a supplier provides concrete evidence of their track record and reliability. Case studies offer insights into the supplier’s problem-solving capabilities and operational efficiency, while references give a personal account of their business conduct and customer service. These tools are essential for evaluating a supplier’s past performance and can help predict the success of your future partnership, significantly reducing the risks associated with onboarding a new supplier for your business needs.

7) How long does it usually take from the moment I place an order until I receive the goods?

Understanding lead time is vital as it directly influences production planning, inventory control, cash flow, customer satisfaction, and competitive positioning. Knowing when materials or products will arrive dictates your scheduling, helps maintain optimal inventory levels, and ensures capital isn’t unnecessarily tied up. Moreover, reliable lead times are crucial for meeting customer expectations and staying agile in a dynamic market, providing a distinct competitive advantage by enabling faster response to demand.

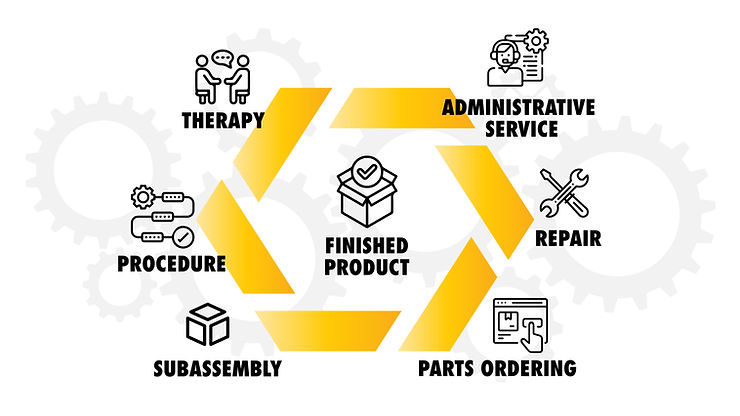

Consultation: The initial phase where client needs are assessed.

- Therapy: A stage that could involve detailed planning or problem-solving.

- Procedure: The actual operational or production process.

- Subassembly: A phase where parts are assembled to create a subsection of the final product.

- Parts ordering: Ordering the necessary components for the product or service.

- Repair: A stage for fixing any issues that might have been identified.

- Administrative service: Administrative tasks that support the process, likely including processing orders and logistics.

- Finished product: The final stage where the product is completed and ready for delivery.

In manufacturing, each stage—from initial consultation to the delivery of the finished product—adds to the total lead time. Streamlining these stages, such as through automation and process improvements, can reduce lead time. This efficiency allows for quicker product delivery, lower inventory costs, and better market responsiveness.

Questions To Ask Before Choosing a Supplier

So, these are the seven essential questions to ask before choosing a supplier. By addressing these queries, businesses can ensure that they’re selecting a partner who aligns with their strategic goals, operational needs, and ethical standards. The right supplier does more than just supply goods or services—they play a crucial role in the efficiency and success of your business. A thorough vetting process that includes these questions will help prevent future issues, foster a reliable partnership, and ultimately support your business’s growth and stability. Make sure your supplier not only meets your current requirements but is also prepared to grow and adapt with your business in the dynamic market landscape.